Hey,

Still fairly new to this hobby and have lots of ideas but I’ve got a snag with a few prints now and was hoping someone could help me work out what I’m doing wrong.

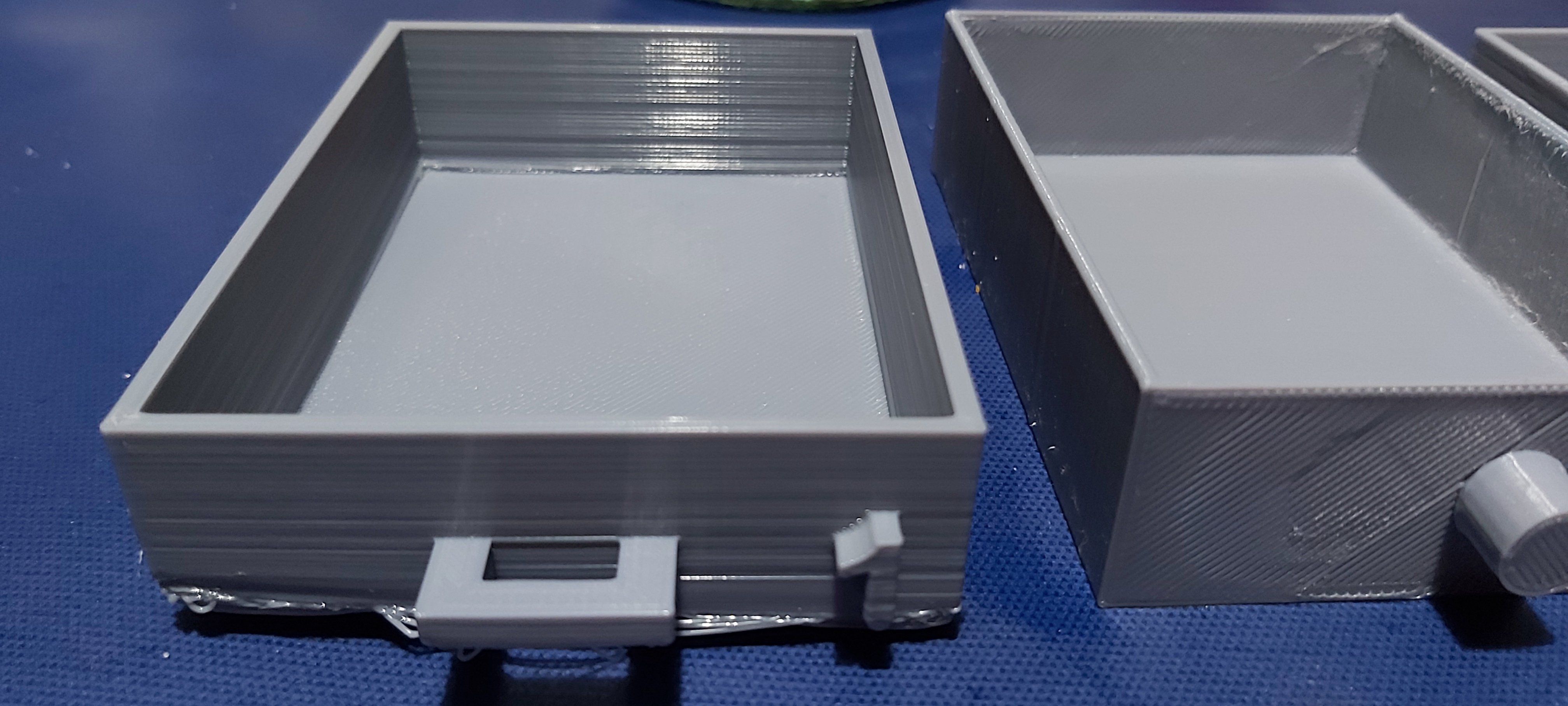

The project is small trays for a custom advent calendar but as you can see the corner on the second picture has lifted massively.

This has happened before with a different print too and I never solved that issue either.

Using an Ender 3 Pro with some generic filament from amazon, hot end at 200C (goes stringy any higher), bed was 50C for this print I think.

Any help would be wonderful :)

Pointy corners like to lift. Try designing with a small radius if possible. A brim helps a lot. Also print so that the long edge of the part is on the X axis for bed slingers.

This is an example I am currently printing with a 10mm brim:

Why on x? I haven’t heard this before

The shorter side on the X makes less air movement across the bed thus retaining more heat in a localized area. Think of all printer motions like little fans themselves. Moving a palm frond or paper fan moved in a large motion moves more air.

The moving bed and undesired cooling it causes is one of the largest weak spots in Cartesian printers.

So on a bed slinger you can orient a print any way you want.

But, a bed slinger has a lot more mass to move when moving the Y axis (the bed, your print attached to the bed) then it does on the X (the gantry and tool head)

So orienting your print where longer moves are on the X axis has a couple benefits

You’ll see something similar with Voron prints where some orient the infill to be at 45 degrees since that overall works best with how CoreXY AB motors work. E.g. only one motor is pulling vs both working in tandem at other angles.

https://github.com/AndrewEllis93/Ellis-SuperSlicer-Profiles?tab=readme-ov-file#45-degree-profile-vs-standard-profile

That depends on the type of print. The design the OP showed will not have such a ringing issue with something large and low. The problem is a lifting corner. The long Y orientation is wrong for this problem.